In a rapidly evolving wellness market, brand differentiation and product quality are no longer optional—they are essential.As demand for innovative dietary supplements grows, many health and wellness brands are turning to contract manufacturers (CMOs) to bring their formulations to life efficiently, cost-effectively, and at scale.

But what exactly does dietary supplement contract manufacturing involve? And how can brands ensure they’re choosing the right partner for success?

Understanding Contract Manufacturing in the Supplement Industry

At its core, contract manufacturing allows supplement brands to outsource the production of their products to third-party specialists. These manufacturers provide the infrastructure, equipment, regulatory compliance, and often even product development services, enabling brands to focus on what they do best—marketing, branding, and distribution.

This model is especially valuable for small to mid-sized businesses that want to avoid the substantial capital investment required to set up manufacturing operations.

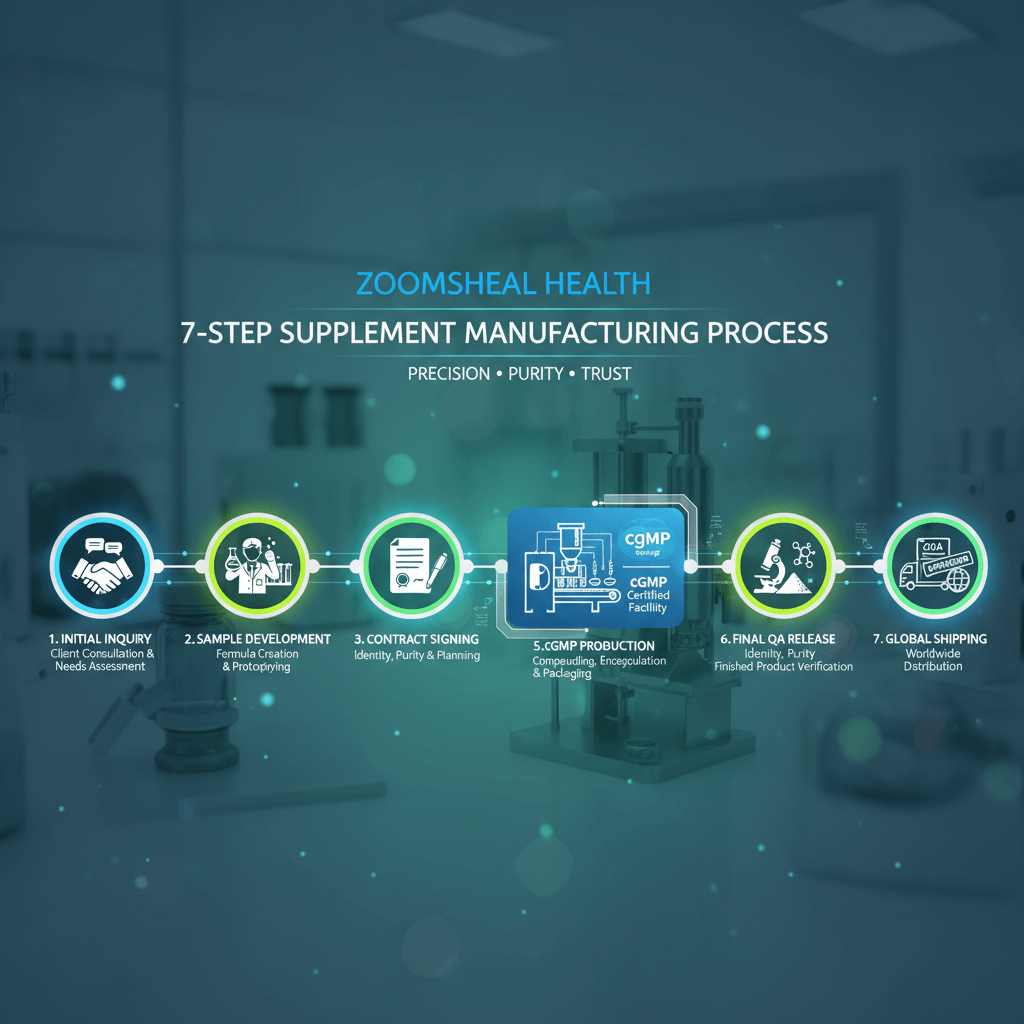

Step 1: Custom Formulation Development

For many brands, the journey begins not with production—but with formulation.

Modern supplement consumers are more discerning than ever. They expect products that are not only effective, but also clean-label, evidence-based, and aligned with specific health goals (e.g., immune support, cognitive function, sleep, gut health). A reputable CMO often offerscustom formulation services, bringing together nutritionists, chemists, and product developers to tailor a supplement based on desired outcomes, dosage formats (capsules, powders, gummies, etc.), and target market.

Key services at this stage may include:

-

Ingredient sourcing and vetting

-

Scientific literature review and efficacy validation

-

Dosage optimization

-

Sensory and stability testing

-

Allergen and regulatory considerations

Step 2: Regulatory Compliance & Quality Assurance

One of the most critical roles of a supplement contract manufacturer is ensuringregulatory compliance. In the U.S., dietary supplements fall under the jurisdiction of the FDA and must comply withCurrent Good Manufacturing Practices (cGMP).

A qualified CMO provides:

-

Full traceability of ingredients

-

COAs (Certificates of Analysis) for each batch

-

In-house or third-party lab testing

-

Label review for FDA and global compliance

-

Support for international export documentation

For brands expanding into markets like the EU, Middle East, or Asia-Pacific, a CMO withmulti-region compliance expertisecan offer a significant advantage.

Step 3: Manufacturing & Packaging

Once a formulation is finalized and approved, the production phase begins. A well-equipped contract manufacturer will offerflexible production capabilitiessuited to your brand’s growth stage.

-

Scalable batch sizes– from pilot runs to large-scale production

-

Wide dosage formats– capsules, softgels, tablets, powders, liquids, sachets

-

Custom packaging– bottles, pouches, blister packs, cartons, private label printing

Efficient turnaround time and packaging versatility are often differentiators in this stage—especially for seasonal or trending products that need to reach market fast.

Step 4: Logistics, Fulfillment & After-Sales Support

A full-service CMO doesn’t stop at production. Many also support:

-

Inventory storage (warehousing)

-

Labeling and barcoding

-

Drop shipping or bulk fulfillment

-

Reorder management and forecasting

-

Batch recalls and lot tracking

This ensures the entire supply chain—from formulation to the customer’s doorstep—is streamlined and monitored.

Benefits of Working with a Trusted CMO

Choosing the right manufacturing partner isn’t just about capacity—it’s aboutshared visionandlong-term collaboration.

Benefits include:

-

Faster time-to-market

-

Reduced operational risks

-

Enhanced product innovation

-

Cost control and predictability

-

Access to R&D expertise without in-house investment

What to Look For in a Contract Manufacturing Partner

Not all CMOs are created equal. When vetting potential partners, brands should consider:

-

Certifications: cGMP, NSF, ISO, Halal, Kosher

-

Track record with similar product types

-

Ingredient transparency and ethical sourcing

-

Communication and collaboration style

-

Flexibility to adapt as the brand scales

From Concept to Commercial Success

Contract manufacturing has become a cornerstone of the supplement industry—empowering brands to innovate, grow, and thrive without building factories of their own. From early-stage formulation to full-scale production and fulfillment, a skilled CMO can transform a product idea into a market-ready solution.

For brands seeking bothagility and reliability, choosing the right manufacturing partner is one of the most strategic decisions they will make.